Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

Cyclone desander filters are essential components in modern water treatment systems, designed to efficiently remove sand and solid particles from water streams. By leveraging the principles of centrifugal force, these filters operate continuously without the risk of clogging, ensuring a steady flow of clean water. Their innovative design not only enhances the separation process but also protects downstream equipment from abrasion and damage, significantly improving overall system efficiency. In this article, we will explore the operational mechanisms, advantages, and applications of cyclone desander filters in optimizing water treatment processes.

Cyclone desander filters work by spinning water rapidly inside a conical chamber, causing solid particles like sand to separate from the water. When water enters the filter tangentially, it creates a swirling motion, or vortex. This vortex forces heavier particles outward toward the chamber walls. These particles then slide down the cone due to gravity and fluid inertia, collecting at the bottom where they can be removed. Meanwhile, cleaner water moves upward through a central pipe and exits for further use.

This design allows continuous operation without clogging since no filter cloth or mesh is involved. The solid particles are separated purely by physical forces, making the process efficient and reliable. The manual valve at the bottom helps flush out accumulated solids easily, ensuring smooth operation.

Centrifugal force is the key to how cyclone desanders separate solids from liquids. As the water spins inside the filter, particles with higher density experience a stronger outward force pushing them to the cyclone’s walls. Lighter water moves inward and upward, leaving the heavier solids behind.

This force, combined with gravity, ensures that even very fine sand particles settle out effectively. The faster the water spins, the stronger the centrifugal force, improving separation efficiency. However, maintaining proper water inlet pressure is crucial to creating this strong rotational flow.

The interaction of centrifugal force, gravity, buoyancy, and fluid dynamics inside the cyclone makes it possible to separate particles based on size and density without any moving parts. This simplicity reduces maintenance needs and extends equipment life.

Maintaining the recommended water inlet pressure is vital to ensure the cyclone desander generates sufficient centrifugal force for effective particle separation.

Cyclone desander filters handle varying flow rates depending on their design and size. Selecting the right flow rate ensures the system processes water efficiently without compromising separation quality. For example, smaller models may handle up to 10 tons per hour, while larger units can process over 500 tons per hour.

Water inlet pressure is critical to generating the necessary centrifugal force inside the cyclone. Typically, a minimum pressure of 0.2 to 0.3 MPa is required. If pressure falls below this range, the swirling motion weakens, reducing sand separation efficiency. Conversely, too high pressure may cause excessive wear or damage. Maintaining stable pressure optimizes performance and extends equipment life.

Materials used for cyclone desander filters must withstand harsh environments, including exposure to abrasive particles and corrosive water. Stainless steel is a common choice due to its excellent corrosion resistance and durability. In some cases, specially coated metals or composites may be used to enhance wear resistance further.

Choosing the right material reduces maintenance frequency and prevents premature failure. It also ensures the filter maintains structural integrity under high pressure and continuous operation, which is essential for reliable water treatment.

Cyclone desanders separate solid particles based on size and density. They are effective at removing sand and silt particles typically larger than 40 microns. The exact separation size depends on the cyclone’s geometry, flow rate, and water pressure.

For example, a well-designed cyclone can remove particles as small as 30 to 50 microns consistently. This capability helps protect downstream equipment like pumps and membranes from abrasion and clogging. Knowing the particle size distribution in your water source helps select a cyclone model optimized for your needs.

Regularly monitor and adjust water inlet pressure to maintain optimal centrifugal force and maximize particle separation efficiency in your cyclone desander system.

Cyclone desander filters excel at removing sand and solid particles from water streams with remarkable efficiency. Their design allows continuous operation, handling large volumes of water without interruption. For example, depending on the model, they can process anywhere from 10 to over 500 tons per hour. This high throughput capacity makes them ideal for large-scale water treatment systems where uninterrupted flow is essential.

Because these filters rely on centrifugal force rather than physical screens, they avoid clogging issues common in traditional filters. This results in consistent separation performance and minimal downtime. The ability to maintain efficiency even when processing water with varying sand concentrations ensures reliable protection for downstream equipment like pumps and membranes.

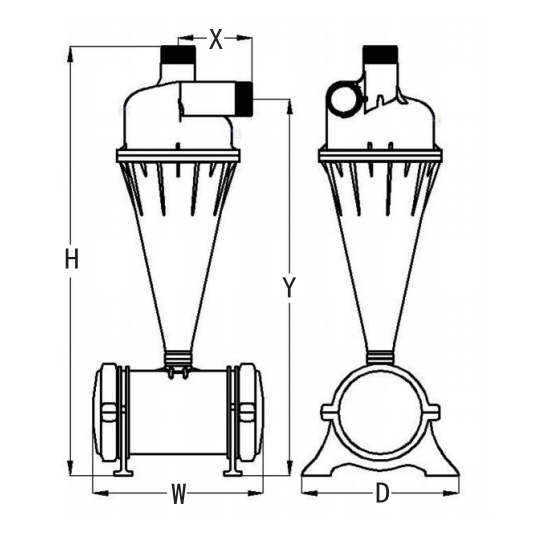

One of the standout advantages of cyclone desander filters is their compact footprint. Their vertical, conical shape requires less installation space compared to other sand removal equipment. This compactness simplifies integration into existing water treatment setups, especially where space is limited.

The simple internal structure also reduces the need for extensive piping or auxiliary components. This streamlines the overall system design, saving on installation costs and allowing for easier maintenance access. Operators benefit from a neat, organized setup that maximizes floor space while delivering high performance.

Cyclone desander filters require minimal maintenance due to their straightforward design. Since they have no moving parts or filter media, common issues like filter cloth clogging or mechanical wear are eliminated. The sand and solids collect at the bottom of the cone and can be flushed out easily through a manual valve.

Routine inspection and occasional cleaning suffice to keep the system running smoothly. This low maintenance need reduces labor costs and downtime, increasing overall operational reliability. Additionally, the robust materials used, such as stainless steel, ensure long service life even in harsh water conditions.

The stable pressure loss during operation means the system maintains consistent performance without frequent adjustments. This stability contributes to predictable maintenance schedules and better process control.

Regularly monitor the sand discharge valve to prevent buildup, ensuring your cyclone desander filter maintains peak efficiency and reduces maintenance efforts.

Cyclone desander filters play a vital role in water treatment systems by removing sand and suspended solids from raw water sources. They help protect downstream equipment like pumps, membranes, and filters from abrasion and clogging. By efficiently separating out particles larger than about 40 microns, they improve water clarity and reduce turbidity, ensuring safer and cleaner water for industrial, municipal, or agricultural use.

These filters are especially useful in treating river water, well water, or recycled water where sand content is high. Their continuous operation capability means water treatment plants can maintain steady flow rates without frequent interruptions for cleaning or maintenance. This reliability boosts overall system efficiency and lowers operational costs.

In mining and mineral processing, cyclone desander filters remove sand and fine particles from slurry streams. This separation improves the quality of the slurry, preventing wear and damage to pumps, pipelines, and processing equipment. It also aids in recovering valuable minerals by ensuring that coarse particles do not interfere with downstream separation techniques.

Because mining operations often handle large volumes of abrasive material, cyclone desanders’ robust design and corrosion-resistant materials make them well-suited for these harsh environments. They support continuous processing, minimizing downtime and labor costs. Additionally, effective sand removal helps reduce environmental impact by limiting sediment discharge into surrounding areas.

The oil and gas industry relies on cyclone desander filters to clean drilling fluids and produced water. These filters remove sand, silt, and other solids that could damage drilling equipment or reduce production efficiency. By maintaining cleaner fluids, they protect pumps, valves, and pipelines from erosion and clogging.

Cyclone desanders also help prevent wellbore damage by removing abrasive particles before fluids are reinjected or discharged. This prolongs equipment lifespan and reduces maintenance frequency. Their compact design allows easy integration into drilling rigs and processing units, where space is often limited.

When selecting cyclone desander filters for your application, consider the specific particle size, flow rate, and operating pressure to ensure optimal separation and equipment protection.

Regular inspection is crucial to keep cyclone desander filters working efficiently. Check the sand discharge valve often to ensure it isn’t blocked. A clogged valve can cause sand buildup, reducing separation efficiency and increasing wear on the equipment. Inspect the interior of the cone and the outlet pipes for any signs of sediment accumulation.

Cleaning frequency depends on water quality and usage. For water with high sand content, clean the filter more often to prevent excessive buildup. Flushing the accumulated sand through the manual valve at the bottom regularly helps maintain smooth operation. Neglecting cleaning can lead to reduced flow rates and increased pressure drop, harming overall system performance.

Maintaining the correct water inlet pressure is vital for cyclone desanders to generate the centrifugal force needed for effective separation. Pressure below the recommended range (usually 0.2 to 0.3 MPa) weakens the vortex, allowing sand particles to remain suspended in the water. On the other hand, too high pressure can cause unnecessary wear or damage.

Use pressure gauges to monitor inlet pressure constantly. Adjust pumps or valves as needed to keep pressure within the optimal range. Stable pressure ensures consistent sand removal and prolongs the filter’s lifespan. Sudden pressure drops or spikes should be investigated immediately to prevent operational disruptions.

Excessive sand buildup inside the cyclone desander can reduce efficiency and increase maintenance needs. To prevent this, ensure the sand discharge valve is functioning properly and open it regularly to flush out collected solids. Avoid long intervals between cleanings, especially when treating water with high sediment loads.

Installing a pressure relief or monitoring system can alert operators to abnormal sand accumulation. Also, consider the flow rate and pressure settings, as improper operation can lead to faster sand buildup. Proper maintenance scheduling based on operational data helps keep sand levels manageable and the system running smoothly.

Schedule routine inspections and cleanings based on water quality and usage to prevent sand buildup and maintain peak cyclone desander performance.

Cyclone desander filters play a significant role in promoting environmental sustainability. By efficiently removing sand and solid particles from water streams, they help reduce sediment discharge into natural water bodies. This prevents water pollution and protects aquatic ecosystems from harmful sedimentation.

Moreover, these filters minimize the need for chemical treatments in water purification, lowering the chemical load released into the environment. Their ability to separate solids without using filter media means less waste generation compared to traditional filtration methods.

In industries such as mining and oil and gas, cyclone desanders limit the release of abrasive particles that could degrade soil and waterways. This containment supports compliance with environmental regulations and reduces the risk of fines or remediation costs.

By ensuring cleaner water discharge and reducing resource consumption, cyclone desander filters contribute to sustainable water management practices. Their efficient operation also helps conserve energy by reducing the workload on downstream equipment.

Using cyclone desander filters offers notable economic benefits. Their simple design with no moving parts means fewer breakdowns and lower repair costs. The robust materials, often stainless steel, resist corrosion and wear, extending the filter's service life.

Because they handle large volumes continuously without clogging, these filters reduce downtime and labor costs associated with maintenance. Operators spend less time cleaning or replacing filter media, improving overall productivity.

The energy efficiency gained by protecting pumps and membranes from abrasion translates into lower operational expenses. Equipment lasts longer, and costly replacements or repairs are minimized.

Additionally, cyclone desanders’ compact design saves space, reducing installation costs and allowing easier integration into existing systems. This space efficiency can translate into lower facility expenses.

Investing in cyclone desander filters thus provides a strong return by cutting maintenance, energy, and replacement costs while ensuring reliable, long-term operation.

Regularly monitor discharge points and maintain proper water inlet pressure to maximize your cyclone desander filter’s lifespan and cost savings.

Cyclone desander filters enhance water treatment efficiency by using centrifugal force to separate sand and solids without clogging. Their compact design, low maintenance needs, and high processing capacity make them ideal for various applications, including mining and oil industries. About ARKA - 30 Years of Excellence in Water Filtration offers high-quality cyclone desander filters that provide reliable performance and environmental benefits. Investing in these filters ensures reduced maintenance costs and sustainable water management, showcasing their value in industrial and municipal settings.

A: A Cyclone Desander Filter is a device that uses centrifugal force to separate sand and solid particles from water, enhancing the efficiency of water treatment systems.

A: Cyclone Desander Filters improve efficiency by continuously removing sand and solids without clogging, protecting downstream equipment and ensuring consistent water flow.

A: Proper water inlet pressure is crucial for generating the centrifugal force needed for effective particle separation in Cyclone Desander Filters.