Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

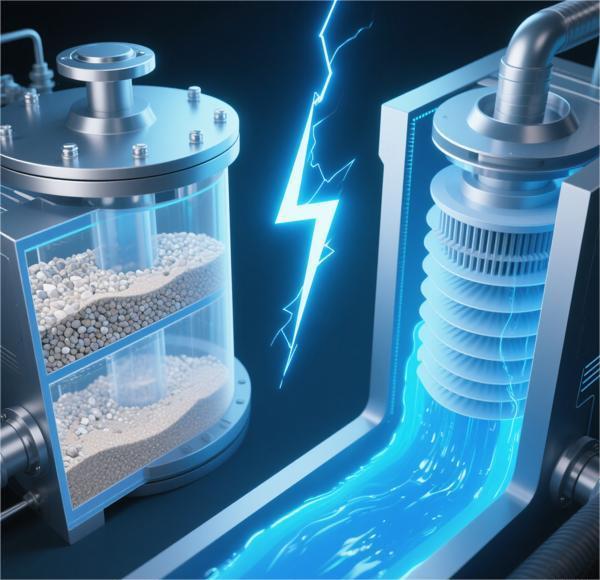

Water filtration stands as the cornerstone of successful drip irrigation systems. Without proper filtration, even the most sophisticated irrigation setup can fail due to clogged emitters and reduced water flow. Among the various filtration options available, sand filters and disc filters have emerged as the two most popular choices for agricultural and commercial irrigation applications.

This comprehensive guide explores the fundamental differences between these filtration systems, helping you make an informed decision based on your specific irrigation needs, water quality, and operational requirements.

Sand filters are the workhorses of physical water treatment, a technology whose roots reach back to the earliest municipal supplies of the 19th century and whose relevance remains undiminished today. Their longevity is no accident: depth filtration through graded mineral media is simple in concept, yet extraordinarily robust in execution.

At the heart of the system lies a bed of carefully selected quartz sand or, where higher density is desired, crushed granite. The individual grains are far from uniform; they are angular, sub-angular, and occasionally sub-rounded, with effective sizes ranging narrowly from 0.66 mm to 1.5 mm in diameter. This deliberate gradation creates a tortuous, three-dimensional labyrinth of voids and interstices. Coarser particles lodge near the top of the bed, while progressively finer material is captured deeper down, producing a self-organising filter matrix whose efficiency actually improves as contaminant load increases.

Hydraulic Loading: 5–15 m³/m²·h is typical for agricultural units; municipal designs may operate at lower rates for finer effluent quality.

Turbidity Reduction: Easily achieves <5 NTU from influent turbidities of 100–200 NTU.

Contaminant Spectrum: Efficient against algae cells, diatoms, pollen, silt, clay flocs, oxidised iron/manganese precipitates, and zooplankton.

Backwash Cycle: Triggered by either pressure differential (0.3–0.5 bar) or elapsed time. Backwash involves a brief, high-rate up-flow (20–40 m³/m²·h) that fluidises the bed, expands it by 20–30 %, and scours accumulated solids to waste.

Orchards and Perennial Crops

Apple, pear, and stone-fruit growers drawing from earthen reservoirs or seasonally turbid streams rely on sand filters to protect micro-sprinklers and drip emitters rated at 0.8–1.2 mm orifices. A single 48-inch vertical steel vessel can treat 40–60 m³/h, sufficient for 10–15 ha of high-density planting.

Row-Crop Irrigation

Maize, soybean, and cotton operations using centre-pivots often pump directly from rivers. Sand filtration upstream of screen or disc units removes coarse organics, preventing nightly algae blooms from clogging nozzles and gear-driven heads.

Greenhouse and Hydroponic Systems

Closed-loop nutrient solutions can become laden with root hairs, peat fines, and biofilm particles. Side-stream sand filters (often stainless steel for corrosion resistance) maintain solution clarity and reduce pathogen load without chemical flocculation.

Aquaculture & Pond Management

Raceways and recirculating aquaculture systems (RAS) deploy pressurised sand filters to polish water returning from biofilters, removing heterotrophic bacterial flocs and residual feed fines that could stress fish gills.

Large-Scale Turf and Landscape

Golf courses and sports fields irrigated with reclaimed wastewater or lake water use skid-mounted duplex sand filter sets to achieve <2 NTU—critical for maintaining ultra-violet (UV) disinfection efficiency downstream.

Disc filters are the product of decades of polymer engineering and precision moulding, offering a compact, modular solution that has quietly displaced older screen technologies in many irrigation markets.

Rather than relying on a single planar mesh, disc filters stack dozens of grooved, colour-coded discs into a cylindrical cartridge. Each disc is injection-moulded from either high-impact polypropylene (PP), glass-fibre-reinforced nylon, or EPDM rubber for chemical resistance, and features a precise sinusoidal or cross-cut groove pattern. When compressed under a calibrated spring stack (or, in high-flow units, a hydraulic piston), the grooves intersect to create a three-dimensional labyrinth with a tortuosity factor many times greater than the apparent mesh rating. This geometry not only increases effective surface area but also generates secondary flow vortices that keep the upstream side of each groove partially scoured, delaying clogging and extending run-time between backwash cycles.

Greenhouse and Hydroponic Operations

Precise fertigation demands micron-level filtration to protect labyrinth emitters and pressure-compensated drippers rated at 0.6–1.0 mm. Manifold-mounted duplex disc skids allow one side to backwash while the other continues to supply NFT channels or rockwool slabs, ensuring zero downtime during critical irrigation windows.

Small-Scale Drip and Micro-Spray

Vineyard and orchard blocks of 1–10 ha often rely on bore water with low suspended solids (<50 mg/L) but occasional rust flakes or biofilm slugs. A single 2-inch, 130-micron disc filter mounted on a mobile trailer provides plug-and-play protection for seasonal drip-tape installations.

Municipal Water “Polishing”

In peri-urban areas where growers purchase treated effluent, disc filters act as a final barrier downstream of UV or ozone systems, removing residual floc that might harbour pathogens. The small footprint (0.2 m² for 25 m³/h) fits easily inside existing pump houses.

Space-Constrained Installations

Rooftop gardens, vertical farms, and containerised nurseries value the vertical stacking capability: a 4-unit tower (0.6 m diameter × 1.5 m height) can treat 100 m³/h—impossible with horizontal sand vessels that would require 4–6 m² of floor space.

High-Frequency Pulse Irrigation

Automated pulsed-drip systems (e.g., pulse-width modulation for strawberries) benefit from the rapid backwash cycle. Because disc filters recover full flow within 10–15 seconds, pressure spikes are minimal and irrigation uniformity is preserved.

Sand Filter

Depth filtration occurs over the entire height of the bed. Water encounters progressively smaller interstitial voids as it descends; the upper 5–10 cm traps coarse debris, mid-depth captures medium silt, and the lower 5 cm acts as a polishing layer. Biological ripening further refines cut-point because the biofilm that colonises sand grains reduces effective pore size by 10–20 % after the first few weeks of operation. The result is simultaneous removal of algae, organic flocs, and mineral particles without any single layer becoming the sole barrier.

Disc Filter

Filtration is limited to the two-dimensional interfaces where adjacent discs meet. Each 0.2–0.5 mm deep groove acts as a micro-channel; when two discs are compressed, the crossing grooves form an “X” vertex that becomes the actual pore throat. Particle retention is therefore strictly at these vertices, giving a sharp cut-off at the rated micron value. There is no secondary capture zone deeper in the media; once the vertex is bridged, the flow path is blocked and pressure drop rises steeply.

Sand Filter

Organic matter: Algae cells (20–200 µm) and plant debris lodge in the upper layers; extracellular polymeric substances (EPS) adhere to sand, improving capture efficiency over time.

Clay and colloids: 2–20 µm particles penetrate deeper but are trapped by the lower, tighter zones; turbidity reduction of 90–98 % is routine.

Biological benefit: Nitrifying bacteria colonise the bed, metabolising ammonia that might otherwise foul emitters, thereby adding a secondary water-quality function.

Disc Filter

Inorganic solids: Sand grains, rust flakes, and mineral precipitates are reliably stopped at the groove vertices; 95–99 % removal of particles ≥ rated micron.

Sticky organics: Biofilm fragments or filamentous algae can smear across the flat disc faces, creating a slimy film that prevents full vertex closure during backwash and can lead to bypass. Efficiency drops sharply under heavy algal loading (>50 mg/L) unless discs are manually cleaned.

Sand Filter

Backwash volume: 2–5 % of daily throughput; a 100 m³/h system may discharge 2–5 m³ per cycle.

Flow demand: Requires 30–50 m³/m²·h superficial velocity to fluidise the bed—roughly 3–4 times the normal service flow—dictating larger pumps or dedicated backwash pumps.

Frequency: Typically every 24–72 h under agricultural loading.

Media replacement: Quartz sand loses angularity and fines are produced; complete change-out every 2–3 years or when pressure drop across a clean bed exceeds 0.15 bar.

Disc Filter

Backflush volume: 0.5–1.5 % of daily throughput; the same 100 m³/h system uses 0.5–1.5 m³ per cycle.

Flow demand: Needs only 15–20 m³/m²·h for 5–15 s; no auxiliary pump is required if system pressure is ≥2 bar.

Frequency: 2–4 cycles per day under moderate loading, triggered at 0.3–0.5 bar ΔP or by timer.

Disc service: Annual removal for visual inspection; ultrasonic or manual brushing if biofilm persists. Disc stack replacement only when groove edges are visibly rounded (<5 years in most field conditions).

Sand Filter

Capital: Steel or FRP tank, under-drain, valves, and larger pump skid result in 30–50 % higher purchase price compared to an equivalently rated disc filter.

Installation: Needs concrete pad, inlet/outlet manifolds, and backwash drain trench; labour hours are 2–3 times higher.

Operating: Energy for backwash pump, periodic sand top-up (5–10 % per year), and disposal fees for spent media.

Disc Filter

Capital: Injection-moulded housing, polypropylene discs, and a small control head keep purchase price low; a 2-inch unit typically costs 40–60 % of a 14-inch sand filter with similar nominal flow.

Installation: Wall-mount brackets or small skid; no drain trench required—backflush hose can route to any nearby drain point.

Operating: Minimal energy (only the small pressure loss during filtration and backflush); disc replacement cost is modest, usually <15 % of original unit price after 3–5 years.

Sand Filter

Footprint: A single 24-inch diameter vessel requires 1.5 m × 1.5 m floor space plus 1 m service access on all sides; duplex installations for continuous flow double this.

Height: Overall height 1.8–2.2 m, limiting placement under low ceilings.

Civil works: Concrete pad with minimum 150 mm thickness to support 1–2 t of wet sand.

Disc Filter

Footprint: A 2-inch twin-unit assembly occupies 0.4 m × 0.4 m; a 4-inch manifold cluster with six cartridges fits within 0.9 m × 0.9 m.

Height: 0.6–1.0 m overall, allowing shelf or wall mounting.

No civil pad required beyond standard pump-house flooring.

Sand Filter

Hardware: Motorised butterfly valves with limit switches can initiate backwash, but valve torque and sand bed expansion require robust actuators (often 230 V AC).

Control: Programmable Logic Controllers (PLCs) with ΔP sensors are available, but integration with cloud-based irrigation platforms is uncommon; remote monitoring usually limited to pressure readings.

Feedback: Bed expansion height and backwash clarity are not routinely monitored, so optimisation relies on operator experience.

Disc Filter

Hardware: 24 V DC solenoid valves or small gear motors perform disc separation and backflush; power draw <10 W per cycle.

Control: Native compatibility with most smart irrigation controllers (e.g., Netafim NMC, Rain Bird IQ4); Modbus, LoRa, or Wi-Fi modules transmit ΔP, cycle count, and water temperature to central dashboards.

Feedback: Real-time alerts for excessive ΔP, incomplete backflush, or valve faults; data logging supports predictive maintenance schedules.

The compact design of disc filters makes them attractive for space-constrained installations. Low water consumption during backflushing appeals to environmentally conscious operators and those facing water restrictions.

Maintenance simplicity allows in-house staff to handle routine cleaning and inspection tasks. The modular design enables easy expansion or modification as irrigation needs change.

Disc filters struggle with sticky organic matter that can clog the grooves between discs. Water sources with high algae content or significant organic loads may overwhelm the filtration capacity.

Long-term operation can cause disc wear, gradually reducing filtration precision. While discs can be replaced, the cost may approach that of a new filter system in some cases.

Your water source contains high levels of organic matter, algae, or turbidity. Wells, ponds, rivers, and streams with challenging water quality typically require sand filtration for reliable operation.

Large-scale operations with high flow rates benefit from the robust performance of sand filters. The initial investment becomes justified when spread across substantial acreage or high-value crops.

Situations where backflush water can be beneficially used, such as disposal on woodlots or boundary vegetation, make the higher water consumption less problematic.

Your water source is relatively clean, such as well water, municipal supplies, or treated groundwater. The precise filtration control allows optimization for specific water quality conditions.

Space constraints limit installation options, making the compact design of disc filters essential. Retrofit applications often favor disc filters for this reason.

Environmental concerns about water consumption or discharge regulations favor the low-water backflushing of disc filters.

Before selecting any filtration system, conduct a comprehensive water quality analysis. Test for particle size distribution, organic content, iron levels, and seasonal variations. This information guides proper filter selection and sizing.

Consider combining filtration technologies for optimal results. A common approach uses sand filters for primary filtration of dirty water, followed by disc filters for final polishing. This combination leverages the strengths of each technology.

Proper sizing ensures adequate filtration capacity while maintaining acceptable pressure loss. Plan for peak demand periods and potential expansion of irrigated areas. Undersized filters lead to frequent backwashing and poor performance.

Establish regular monitoring schedules for pressure differential, backwash frequency, and water quality. Keep detailed records to identify trends and optimize maintenance intervals. Modern systems can provide automated alerts for maintenance needs.

Can I use both sand and disc filters together?

Yes, combining sand and disc filters creates an effective multi-stage filtration system. Sand filters handle primary filtration of dirty water, while disc filters provide final polishing. This approach is particularly effective for challenging water sources that require comprehensive treatment.

How often do sand filters need backwashing?

Backwashing frequency depends on water quality and system usage. In hot climates with dirty water, sand filters may require backwashing every hour during peak irrigation periods. Clean water sources might only need backwashing once or twice daily.

Which filter is better for algae-rich pond water?

Sand filters excel at removing algae and organic matter from pond water. The biological activity within the sand bed helps break down organic compounds, making sand filters the preferred choice for pond and surface water applications.

Do disc filters require electricity to backflush?

Most automatic disc filters require electricity to operate the backflush mechanism, including motors for disc separation and water flow controls. However, manual disc filters can be backflushed without electricity, though this requires more labor.

How long do sand and disc filters last?

With proper maintenance, sand filter tanks can last 15-20 years, though the sand media needs replacement every 2-3 years. Disc filters typically last 10-15 years, with individual discs requiring replacement every 5-7 years depending on usage and water quality.

The decision between sand filters and disc filters ultimately depends on your specific water quality, operational requirements, and budget considerations. Sand filters excel in challenging conditions with high organic loads, while disc filters provide efficient, space-saving solutions for cleaner water sources.

Consider your water source characteristics, available space, maintenance capabilities, and long-term operational goals when making this decision. The right filtration system forms the foundation of a successful irrigation operation, protecting your investment in drip irrigation equipment and ensuring consistent crop production.

For complex water quality situations or large-scale operations, consulting with irrigation professionals can provide valuable insights tailored to your specific needs. The investment in proper filtration analysis and system design pays dividends through years of reliable operation and optimal crop performance.

Explore our comprehensive range of high-quality disc filters designed for reliable performance in diverse agricultural applications.Visit ARKA Irrigation to discover how our filtration solutions can enhance your irrigation efficiency and protect your valuable crops.