Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

Disc filters are innovative water filtration devices that utilize a unique design to efficiently remove suspended solids from various water sources. At the core of their operation is a stack of interlocking plastic discs, each featuring intricate grooves that create a network of filtration pathways. As water is forced through these discs, particles larger than the groove size are trapped, ensuring clean water flows out. This article explores the working principle of disc filters, highlighting their construction, filtration process, and advantages in diverse applications.

Disc filters are ingeniously designed to provide efficient water filtration through a compact and durable structure. Understanding their construction helps appreciate how they achieve high filtration performance and reliability.

At the heart of the disc filter is a stack of multiple plastic discs. These discs are ring-shaped and have intricately engraved grooves on their surfaces. When stacked tightly, the grooves on adjacent discs interlock, forming a complex network of filtration pathways. This layered structure acts like many filter screens combined, trapping particles effectively.

Other essential components include:

● Central Shaft or Spine: Holds the discs firmly together, ensuring proper compression.

● Compression Mechanism: Springs or mechanical devices maintain tight pressure on the discs to keep the grooves aligned.

● Filter Housing: A robust shell made from plastic or metal that encloses the disc stack, directing water flow and protecting the internal components.

● Inlet and Outlet Ports: Allow water to enter and exit the filter system.

● Backwash System: Enables reverse flow to clean the discs and remove trapped debris.

The discs are usually made from high-strength engineering plastics like polypropylene or polyamide. These materials offer excellent corrosion resistance, wear resistance, and can withstand high temperatures. Such durability ensures the filters perform well even in harsh environments, including industrial and agricultural settings.

The housing is often constructed from stainless steel, coated carbon steel, or tough plastics. This choice depends on the application’s pressure requirements and water chemistry. The material must resist corrosion and mechanical stress to guarantee long service life.

Disc filters incorporate several design innovations to optimize filtration and maintenance:

● Groove Geometry: The disc surfaces feature various groove patterns—spiral, wave, or triangular shapes—that increase filtration surface area and improve particle capture.

● Modular Design: Many disc filters allow users to add or remove filter units, adapting capacity to different flow rates or space constraints.

● Automatic Backwash: Modern systems include automated backwashing that reverses water flow, loosening and flushing out accumulated particles. This feature reduces downtime and manual cleaning effort.

● Compactness: The stacked disc arrangement provides a high filtration area in a small footprint, making installation easier in tight spaces.

● Spring Compression: Ensures consistent pressure on the discs, maintaining filtration efficiency even as the filter ages.

These combined elements make disc filters versatile, efficient, and easy to maintain, suitable for a variety of water treatment applications.

Selecting disc filters made from corrosion-resistant plastics and metals enhances durability and reduces long-term maintenance costs in industrial water filtration systems.

Disc filters work by forcing water through a stack of tightly compressed plastic discs. Each disc has grooves on its surface, and when stacked, these grooves interlock to form a complex network of tiny filtration pathways. As water is pushed through, particles larger than the groove size get trapped between the discs. This physical filtration removes sand, dirt, algae, and other suspended solids efficiently. Water then flows out clean through the central core of the discs.

Water distribution is key. Incoming water first hits a diverter that spreads it evenly over the disc surfaces. This ensures all discs filter uniformly, maximizing the filter’s capacity and lifespan. The compression mechanism, usually a spring or mechanical clamp, keeps the discs tightly pressed, preventing particles from bypassing the grooves.

During filtration, water flows from the inlet and passes through the disc stack. The grooves act like many tiny sieves layered together, capturing particles throughout the depth of the discs, not just on the surface. This three-dimensional filtration increases dirt-holding capacity compared to simple screen filters.

Particles get trapped in the narrow spaces formed by the interlocking grooves. The depth and shape of these grooves determine the filter’s precision, which can range from tens to hundreds of microns depending on the disc design. The result is high filtration efficiency with minimal pressure drop, saving energy during operation.

Over time, trapped particles accumulate, increasing pressure inside the filter. When the pressure difference reaches a set threshold, the system triggers backwashing to clean the discs automatically.

Backwashing reverses the water flow, pushing water from the outlet side back through the discs. This flow loosens and flushes out the trapped debris. During this process, the compression on the discs is slightly released to allow particles to be dislodged effectively.

The backwash cycle typically lasts 10 to 20 seconds, making it fast and efficient. After cleaning, the discs are recompressed, and filtration resumes without interrupting the water supply. This automatic cleaning reduces manual maintenance and extends the filter’s service life.

Regularly monitor the pressure differential across the disc filter to optimize backwash timing, ensuring consistent filtration performance and extending equipment life.

Disc filter systems are versatile and highly effective, finding uses across many industries. Their efficient filtration and automatic cleaning make them ideal for various water treatment needs.

In agriculture, water quality is crucial for crop health. Disc filters remove silt, algae, and suspended solids from irrigation water, preventing clogging in drip lines and sprinklers. This ensures even water distribution and reduces downtime. Their automatic backwash feature minimizes manual cleaning, enhancing irrigation system efficiency. Farmers benefit from consistent water flow and reduced maintenance costs.

Industries rely on clean water for processes like cooling, washing, and manufacturing. Disc filters protect equipment such as heat exchangers, boilers, and cooling towers by removing particles that cause wear or scaling. This filtration helps maintain equipment longevity and operational efficiency. The filters handle varying water qualities and flow rates, adapting well to industrial demands. They also reduce the risk of downtime due to clogged pipes or fouled machinery.

Municipal water systems use disc filters to improve raw water quality before further treatment. They serve as pretreatment devices, removing suspended solids that could interfere with disinfection or chemical processes. Disc filters also find use in wastewater treatment plants, reducing particulate loads before biological treatment stages. Their automatic cleaning keeps filtration consistent, supporting reliable public water supply.

Beyond these, disc filters are applied in aquaculture to maintain water clarity and remove waste. They also appear in food and beverage processing, chemical plants, and power stations. Anywhere solid-liquid separation is needed, disc filters offer a dependable solution. Their modular design allows easy scaling for different capacities and space constraints.

When selecting disc filters for specific applications, consider the type and size of particles to be removed and the required flow rate to optimize filtration performance and system longevity.

Disc filter systems offer several key benefits that make them a preferred choice in water filtration across many industries. Their unique design and operational features deliver efficiency, ease of maintenance, and durability, which translate into long-term value and reliable performance.

Disc filters provide highly efficient filtration thanks to their three-dimensional filtration matrix formed by the stacked discs. The interlocking grooves create numerous tiny pathways that trap particles throughout the depth of the discs, not just on the surface. This results in:

● High dirt-holding capacity: The filter can retain more particles before requiring cleaning.

● Precise filtration: Depending on the groove design, filtration accuracy ranges from tens to hundreds of microns, suitable for various water qualities.

● Low pressure drop: Water passes through easily, saving energy during operation.

This efficiency ensures that suspended solids such as sand, silt, algae, and organic matter are effectively removed, protecting downstream equipment and improving water quality.

One of the standout advantages of disc filter systems is their low maintenance demand:

● Automatic backwash: The system automatically reverses water flow to clean the discs when pressure differential rises, reducing manual intervention.

● Quick cleaning cycles: Backwashing typically takes only 10 to 20 seconds, minimizing downtime.

● Reduced water consumption: Compared to other filters, disc filters use less water during backwash.

● Simple manual cleaning: When necessary, discs can be easily disassembled and cleaned without specialized tools.

These features collectively lower labor costs and extend the filter's service intervals, making the system user-friendly and cost-effective to operate.

Disc filters are built to last, using high-strength materials that withstand harsh environments:

● Corrosion resistance: Discs made from polypropylene or polyamide resist chemical attack and degradation.

● Wear resistance: The robust materials tolerate abrasive particles, maintaining filtration performance over time.

● Stable compression: Springs or mechanical clamps keep discs tightly pressed, ensuring consistent filtration even after long-term use.

● Strong housings: Stainless steel or durable plastics protect internal components from damage and pressure.

This durability translates into fewer replacements and repairs, providing reliable filtration and lowering total cost of ownership.

To maximize disc filter longevity, regularly monitor pressure differentials and schedule backwash cycles promptly, preventing excessive particle buildup that can strain the system.

While disc filter systems offer many benefits, users should be aware of certain challenges and limitations to make informed decisions.

Disc filters often require a significant upfront cost. Their advanced design, high-quality materials, and automated features contribute to this investment. For small-scale operations or projects with tight budgets, this initial expense may be a hurdle. However, the long-term savings in maintenance and operational efficiency can offset the initial price over time.

Although disc filters feature automatic backwashing that reduces manual cleaning frequency, they still need regular maintenance. Organic matter, chemical residues, or fine particles can cause discs to stick together, reducing cleaning effectiveness. Periodic manual inspection and cleaning ensure optimal performance and prevent clogging. Neglecting maintenance may lead to reduced filtration quality and system downtime.

Disc filters excel at removing suspended solids but have limited ability to eliminate dissolved contaminants such as chemicals, heavy metals, or salts. These soluble pollutants require additional treatment methods like chemical dosing, membrane filtration, or adsorption processes. Therefore, disc filters are best used as part of a comprehensive water treatment system rather than a standalone solution for all water quality issues.

Evaluate your water treatment goals carefully and combine disc filters with complementary technologies when soluble pollutant removal is necessary for comprehensive water purification.

Selecting the right disc filter system is crucial for ensuring efficient water filtration tailored to your specific needs. Several factors come into play during this decision-making process, including water quality, flow rate, and system size.

First, assess the type and concentration of particles in your water. If the water contains a high level of suspended solids, such as silt or organic matter, opt for a disc filter with finer filtration precision. Conversely, if the water is relatively clean, a filter with coarser grooves may suffice, reducing unnecessary pressure drop and maintenance.

Next, consider the frequency and ease of maintenance. Some systems offer advanced automatic backwash features, which can significantly reduce manual labor and downtime. Evaluate your operational capacity to manage maintenance tasks and choose accordingly.

Also, think about the installation environment. Space constraints might require a compact or modular design, allowing flexibility in filter arrangement and scalability.

Understanding your water quality needs is essential. Different applications demand different filtration accuracies. For example:

● Agricultural irrigation often requires removing particles larger than 100 microns to prevent clogging.

● Industrial processes might need filtration down to 20 microns to protect sensitive equipment.

● Municipal water supply may require even finer filtration to meet health standards.

Testing your water source for particle size distribution and contaminant types helps determine the appropriate disc filter specification.

Disc filters come in various sizes and capacities. Matching the filter's flow rate to your system's demand prevents overloading or underutilization. An undersized filter may clog quickly, increasing maintenance frequency, while an oversized filter can lead to unnecessary expenses.

Calculate your peak and average flow rates, then select a filter that can handle these volumes comfortably. Consider future expansion plans and choose a system that offers modular units or easy scalability.

Always perform a thorough water analysis before selecting a disc filter to ensure the chosen system meets your contamination removal needs and flow requirements effectively.

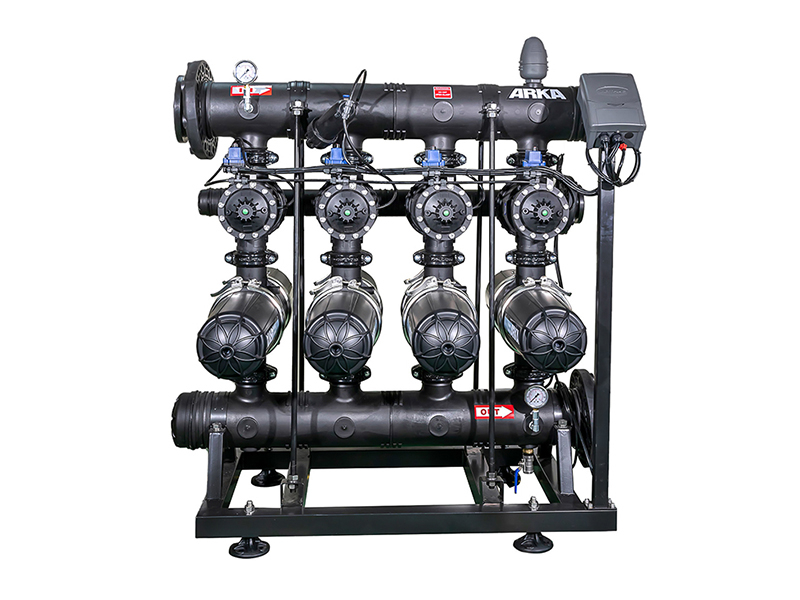

Disc filters efficiently trap particles using interlocking grooves, providing high filtration accuracy and low pressure drop. They are ideal for agricultural, industrial, and municipal water treatment, offering automatic backwashing for reduced maintenance. As water filtration needs evolve, disc filters will continue to adapt, delivering reliable performance and cost-effective solutions. Implementing these systems enhances water quality management. About ARKA - 30 Years of Excellence in Water Filtration offers advanced disc filter systems that combine durability with innovative design, ensuring long-term value and efficient operation in various applications.

A: A Disc Filter System is a water filtration device that uses a stack of interlocking plastic discs with grooves to trap particles, providing efficient filtration for various applications.

A: The Disc Filter System operates by forcing water through tightly compressed discs, trapping particles in the grooves, and using automatic backwashing to clean the discs.

A: Choose a Disc Filter System for its high filtration efficiency, low maintenance needs, and durability, making it ideal for agricultural, industrial, and municipal applications.