Views: 0 Author: Site Editor Publish Time: 2025-09-28 Origin: Site

Cyclone desander filters are essential devices in various industries, designed to efficiently separate sand and solid particles from liquids using centrifugal force. This innovative technology not only enhances fluid purity but also protects critical equipment from abrasive damage. In this comprehensive guide, we will explore the principles of operation, key components, applications, and the numerous advantages of cyclone desander filters, highlighting their significance in oil and gas, water treatment, and manufacturing processes.

Cyclone desander filters use centrifugal force to separate sand and other solid particles from liquids. When the fluid enters the cyclone chamber tangentially, it spins rapidly, creating a vortex. The heavier particles move outward due to centrifugal force, hitting the cyclone walls. Then gravity pulls them down to the bottom collection area. Meanwhile, the cleaner fluid moves upward through the center and exits the cyclone. This process happens continuously and without any moving parts, making it efficient and reliable.

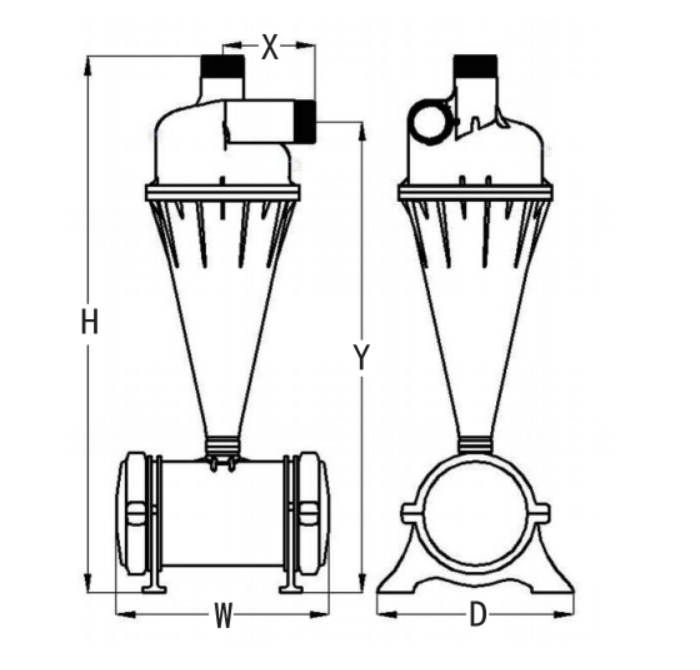

A typical cyclone desander filter consists of several key parts:

● Inlet: Introduces the fluid tangentially to start the spinning action.

● Cyclone body: The conical or cylindrical chamber where separation occurs.

● Outlet for clean fluid: Usually located at the top center, allowing filtered liquid to exit.

● Sand collection chamber: Positioned at the bottom to collect separated particles.

● Vortex finder: A tube extending into the cyclone that helps direct the clean fluid out.

The design focuses on optimizing the vortex strength and particle separation efficiency. Materials used often resist abrasion because sand and solids can wear down surfaces quickly. Sizes and shapes vary depending on the application, flow rate, and particle sizes expected.

Cyclone desander filters differ from traditional filters in several ways:

Feature | Cyclone Desander Filter | Traditional Filters |

Mechanism | Centrifugal separation | Physical barrier or mesh |

Moving parts | None | Often have moving parts |

Maintenance | Low, simple cleaning | Higher, replacing filter media |

Particle size handled | Typically larger particles (> 40 microns) | Can handle finer particles depending on filter type |

Pressure drop | Low to moderate | Can be high depending on clogging |

Suitability | High solid loads, abrasive fluids | Lower solid loads, finer filtration |

Cyclone desanders excel in removing coarse particles quickly without clogging. However, they are less effective for very fine particles, where media filters or membrane systems might be better.

Ensure the cyclone desander’s inlet velocity matches design specs to maximize particle separation efficiency and reduce wear.

In the oil and gas sector, cyclone desander filters play a crucial role in protecting equipment from sand and solid particles. Drilling fluids often carry sand and rock fragments that can damage pumps, valves, and pipelines. Using a cyclone desander filter removes these abrasive particles early in the process, reducing wear and tear and preventing costly downtime. It also helps maintain the quality of drilling mud, which is vital for efficient drilling operations. Cyclone desanders are especially useful offshore, where maintenance can be challenging and expensive.

Cyclone desander filters are widely used in water treatment plants to remove sand and grit from raw water sources. This step prevents clogging and damage to downstream equipment such as pumps, filters, and membranes. By eliminating coarse particles, they improve the overall efficiency of water purification processes. These filters are also common in wastewater treatment, where they remove solids before biological treatment stages. Their ability to handle large volumes of water while requiring minimal maintenance makes them ideal for municipal and industrial water systems.

Many industries rely on cyclone desander filters to protect machinery and improve product quality. For example:

● Mining: Removing sand and grit from slurry reduces abrasion in pumps and pipelines.

● Food and Beverage: Ensuring clean water free of solids helps maintain hygiene standards.

● Chemical Manufacturing: Protecting sensitive equipment from solid contaminants improves process stability.

● Power Plants: Removing sand from cooling water prevents erosion of turbines and heat exchangers.

In these settings, cyclone desanders help maintain smooth operations and reduce maintenance costs. They are favored for their robustness and ability to handle abrasive materials without frequent replacement.

Regularly monitor the particle load in your cyclone desander’s inlet to optimize performance and avoid unexpected equipment wear.

Cyclone desander filters excel at removing larger solid particles from fluids. Their design uses centrifugal force to push heavier particles outward and downward, effectively separating sand and grit. This process happens continuously, allowing high flow rates without clogging. Unlike traditional filters that rely on mesh or media, cyclone desanders handle abrasive particles without frequent blockages or pressure drops.

They typically remove particles larger than 40 microns, making them ideal for protecting sensitive equipment from wear caused by coarse solids. This efficiency reduces downtime and extends the life of pumps, valves, and pipelines. Industries that deal with heavy solids benefit greatly from their reliable particle separation.

One major advantage is cost savings over time. Cyclone desander filters have no moving parts, which cuts down on mechanical failures and maintenance labor. They also avoid the need for expensive filter media replacements common in other filtration systems.

Their robust construction withstands abrasive environments, reducing the frequency of replacements. Installation costs are generally lower as well because they don’t require complex support systems or frequent servicing. Over the long run, these savings add up, making cyclone desanders a smart investment for many industries.

Maintenance is straightforward and minimal. Since the cyclone uses centrifugal force rather than physical barriers, it avoids clogging issues common in mesh filters. Periodic cleaning of the sand collection chamber suffices to keep the system running smoothly.

Operators rarely need to dismantle internal parts, which saves time and reduces the risk of accidental damage. This low-maintenance nature makes cyclone desanders especially attractive in remote or offshore locations where frequent servicing is difficult or costly.

Schedule regular inspections of the sand collection chamber to maintain peak efficiency and prevent buildup that could reduce performance.

Cyclone desander filters excel at removing larger particles, but they struggle with fine solids. Particles smaller than about 40 microns often stay suspended in the fluid and pass through the cyclone. This limits their effectiveness in applications needing very fine filtration. For example, in water treatment processes requiring removal of fine silt or clay, cyclone desanders may need to be paired with other filtration methods like media filters or membranes. Operators should understand this limitation to avoid unexpected equipment wear or contamination downstream.

Several factors affect cyclone desander performance. The inlet velocity must match design specifications; too low reduces separation efficiency, too high causes excessive wear. Abrasive particles can erode cyclone surfaces over time, especially if made from less durable materials. Proper material choice, such as hardened steel or abrasion-resistant linings, helps extend service life. Also, maintaining a consistent flow rate avoids pressure fluctuations that reduce separation quality. Operators must monitor these parameters regularly to keep the system running optimally.

Another operational challenge involves handling the collected solids. The sand collection chamber needs regular emptying to prevent buildup that can block flow or cause re-entrainment of particles. Neglecting maintenance may reduce filter efficiency and increase wear on downstream equipment.

While cyclone desanders reduce particle discharge, they do not eliminate all solids from effluent streams. Fine particles passing through can still affect ecosystems if released untreated. Proper disposal or treatment of collected solids is essential to minimize environmental harm. Additionally, worn cyclone parts may generate metal debris, which requires responsible handling.

Cyclone desanders consume no electricity for particle separation, making them energy-efficient compared to some alternatives. However, their installation and maintenance involve material use and waste generation. Operators should consider lifecycle impacts and implement recycling or waste reduction programs where possible.

Regularly inspect cyclone liners and collection chambers to prevent wear-related failures and maintain environmental compliance.

Proper installation ensures cyclone desander filters perform efficiently and last longer. Start by placing the filter in a location that allows easy access for inspection and cleaning. Ensure the inlet pipe connects tangentially to the cyclone body to create the necessary vortex. Avoid sharp bends or obstructions in the inlet piping, as these can reduce flow velocity and separation efficiency.

Use corrosion- and abrasion-resistant materials for mounting brackets and supports to prevent premature wear. The sand collection chamber should be positioned for easy emptying, preferably near a drain or collection container. Make sure the outlet pipe is aligned vertically to prevent backflow or sediment buildup.

Check that the system’s flow rate matches the cyclone’s design specifications. Too low flow reduces separation efficiency, while too high flow increases wear and pressure drop. Install pressure gauges upstream and downstream to monitor performance and detect clogging early.

Routine maintenance keeps cyclone desanders operating smoothly and prevents costly downtime. Begin with regular inspections of the sand collection chamber. Empty it frequently to avoid sediment buildup, which can cause re-entrainment of particles or flow blockages.

Inspect internal surfaces for signs of abrasion or corrosion. Replace liners or worn parts promptly to maintain filtration efficiency. Clean the inlet and outlet pipes to remove any debris that could restrict flow.

Check seals and gaskets to prevent leaks. Lubricate any mechanical components such as valves or access hatches according to manufacturer guidelines. Keep maintenance logs to track wear patterns and schedule replacements before failures occur.

Common issues include reduced separation efficiency, increased pressure drop, and unexpected wear. If efficiency drops, first verify the inlet velocity matches design requirements. Low flow or irregular flow can cause poor particle separation.

High pressure drop may indicate sediment buildup in the collection chamber or blockage in outlet piping. Empty the chamber and clean pipes thoroughly. Inspect for damaged liners or internal parts causing turbulence.

Excessive wear often results from abrasive particles or high flow rates. Upgrade to more durable materials or reduce flow velocity to extend component life. If leaks appear, tighten or replace seals.

If problems persist, consult the manufacturer or a filtration specialist for detailed diagnostics and solutions.

Schedule regular inspections and cleaning to maintain cyclone desander efficiency and prevent costly repairs.

Cyclone desander filters are evolving thanks to new materials and design improvements. Manufacturers now use advanced abrasion-resistant alloys and composite linings that extend equipment life. Computational fluid dynamics (CFD) modeling helps optimize cyclone shapes for better particle separation and lower pressure drops. This leads to filters that handle higher flow rates and tougher solids more efficiently.

Additive manufacturing (3D printing) enables complex internal geometries previously impossible to produce. These designs improve vortex stability and reduce wear points. Some companies experiment with hybrid systems combining cyclones and other filtration technologies to capture finer particles. These innovations make desanders more versatile and effective across industries.

Smart technology integration transforms cyclone desander filters into intelligent devices. Sensors monitor flow rate, pressure drop, and particle load in real time. Data connects to control systems for automatic adjustments, ensuring optimal performance and reducing manual intervention.

Predictive maintenance uses sensor data and machine learning algorithms to forecast wear or blockages before failures occur. This minimizes downtime and maintenance costs. Remote monitoring allows operators to track filter health from anywhere, improving response times.

IoT-enabled desanders can integrate into larger plant automation systems. This helps coordinate filtration with upstream and downstream processes for smoother operations and energy savings.

Looking ahead, cyclone desander filters will likely become more compact and energy-efficient. New materials may allow operation under higher temperatures and corrosive fluids, expanding their use in harsh environments.

Emerging trends include modular designs that simplify customization and scaling. This helps industries quickly adapt filters to changing process needs. Environmental regulations may drive innovations focused on reducing particle emissions and improving solids disposal methods.

Researchers explore combining cyclones with novel separation techniques like electrostatic or ultrasonic enhancement. Such hybrids could capture finer particles without sacrificing flow capacity.

Overall, future cyclone desander filters will be smarter, tougher, and more adaptable, meeting rising demands across oil and gas, water treatment, and manufacturing sectors.

Invest in cyclone desander filters featuring smart sensors and predictive maintenance to boost reliability and cut operational costs.

Cyclone desander filters efficiently use centrifugal force to separate larger particles from liquids, offering low maintenance and cost-effectiveness. They excel in industries like oil and gas, water treatment, and manufacturing. While they struggle with fine particles, advancements are making them smarter and more adaptable. For those seeking reliable filtration solutions, About ARKA - 30 Years of Excellence in Water Filtration offers innovative cyclone desander filters that enhance operational efficiency and reduce costs, providing significant value across various applications. Explore their products for tailored solutions.

A: A Cyclone Desander Filter is a device that uses centrifugal force to separate sand and other solid particles from liquids, enhancing fluid purity and protecting equipment.

A: It works by introducing fluid tangentially into a cyclone chamber, creating a vortex that separates and collects heavier particles, allowing cleaner fluid to exit.

A: Cyclone Desander Filters efficiently remove sand and grit, preventing equipment damage and improving water purification processes with minimal maintenance.

A: They offer efficient particle removal, cost-effectiveness, low maintenance, and durability, making them ideal for handling abrasive materials in various industries.